The short answer is "Yes".

Load testing polyester roundslings and synthetic web slings in a basket hitch is a practice that is conducted dozens of times each business day in North America, by various sling manufacturers and rigging suppliers.

There are two key elements to successfully testing the sling, while avoiding damage and ensuring the load applied is reasonably distributed throughout the sling component/fiber members.

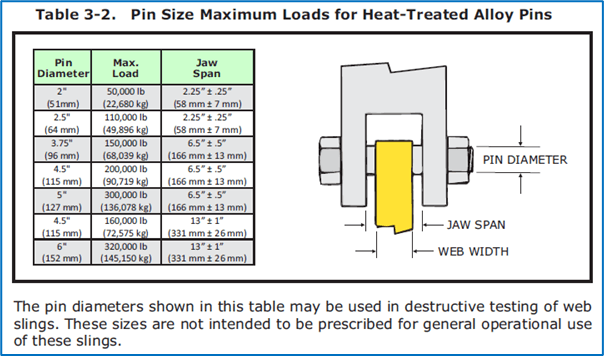

- The minimum test pin diameter as recommended by the Web Sling & Tiedown Association Recommended Standard Specification* documents for either web slings or roundslings should be adhered to (see Table 3.2).

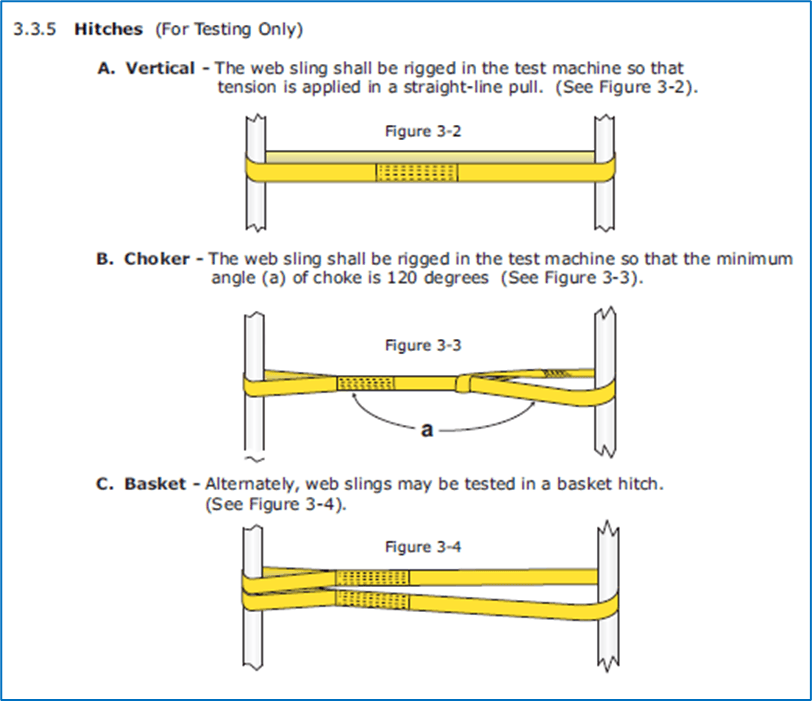

- The test technician should slowly apply force while ensuring alignment and normalization to the sling (legs)** as noted in Figure 3-4, from the WS-1, 2015 document.

The same practice is permitted with synthetic roundslings, based on the information provided by the WSTDA Roundsling Recommended Specifications (RS-1) 2019 document.

*WSTDA-WS-1 (2015), Web Sling & Tiedown Association, Web Sling Recommended Specifications, 2015, Appendix

**WSTDA-WS-1 (2015), Web Sling & Tiedown Association, Web Sling Recommended Specifications, 2015

___

Disclaimer: The information provided above: (i) is intended only as a general educational resource for Users of our Knowledge Base, and is not intended for a specific use in, and does not constitute advice for, a User’s specific situation; and (ii) may no longer be accurate as of the date of a User’s access due to unforeseen changes to regulations, standards or other factors. By accessing our Website and Knowledge Base, you acknowledge and agree that you are solely and exclusively liable and responsible for your actions arising out of the Website and Knowledge Base, and ITI shall have no liability or responsibility therefore.

For personalized advisement to your organization, please contact ITI at info@iti.com.