Inspector & Technician Simulations

ITI, in collaboration with our industry partners and technical advisors, is developing a robust library of long form simulation to support training, assessment and performance support. ITI inspection and technician simulations can be delivered to a VR headset or standard browser through the ITI Learning Hub.

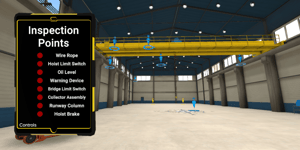

OVERHEAD CRANE INSPECTOR

This practical assessment allows the learner to put their newly acquired skills and knowledge to use by virtually inspecting an overhead crane. ITI inspection simulations track learner progress, provide remedial feedback, and deliver user results to the ITI Learning Hub.

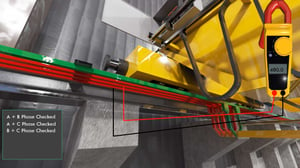

OVERHEAD CRANE TECHNICIAN

This training simulation and practical assessment allows the learner to put their newly acquired skills and knowledge to use by inspecting and troubleshooting systems and components. Technicians can uses a virtual tool kit to replace parts and restore system functionality. ITI inspection simulations track learner progress, provide remedial feedback, and deliver user results to the ITI Learning Hub.

CONSTRUCTION HAZARD IDENTIFICATION TRAINING

ITI- VR Construction Hazard Training allows learners to experience a working construction site while identifying hazards across 10 risk domains, including Falls, Struck by Object, Electrocutions, and Caught-in/between, the “fatal four” dubbed by OSHA.

CONSTRUCTION SAFETY

A bundle of simulated training and assessment tools for Construction Safety Professionals to help reduce accidents and increase hazard awareness.

- Fall Protection

- Trenching and Excavation

- Scaffolding

- Electrical Hazards

- Ladder Safety