The use of multi-part braided slings appears to be returning to the marketplace. In the fabrication of these slings, generally a single wire rope is braided or helically laid back against its own body to form an eye & eye sling. By design it allows the sling to have the relative bendability of the component wire rope plus a high strength value based on the sum of its parts. The number of component wire ropes in a multi-part sling could be as many as nine or as few as three.

One area in which to use multi-part braided slings is the “super heavyweight” category. A lift may require a sling capacity that cannot be achieved by a single part sling, but can be reached by braiding small component wire ropes together into an eye & eye sling configuration.

Example: A 4” single part, swaged E/E sling in a basket has a rated capacity of 226 tons. The same amount can be lifted by using a 7-part, 1-5/8” multi-part sling in a basket hitch.

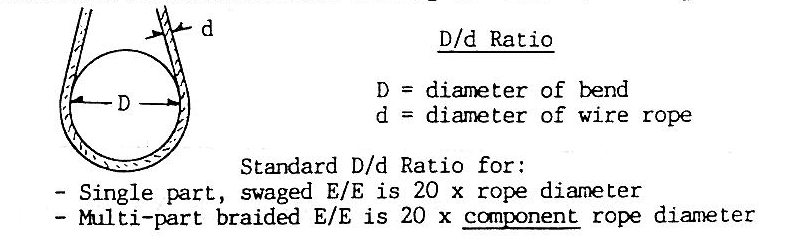

A second and more common reason for selecting multi-part slings is their bendability. If a sling is bent around too small a diameter while making its lift, there is a reduction in lifting efficiency. A ratio has been developed to help determine minimum allowable bending diameter for slings.

Example: A 10” horizontal steel shaft is the lifting attachment for a pre-fabricated structure. Weight is 18 tons. (It is determined a wire rope sling is the best type of sling for this application.)

Options:

a) 1-1/8” single part, swaged E/E in a basket hitch will meet the 18 ton requirement; however the 10” steel shaft is too small for 1-1/8” wire rope when applied to D/d ratio. (The standard minimum bending diameter for 1-1/8” wire rope sling is 22½”.)

b) 6 parts of ½” component wire rope braided E/E in a basket hitch will also meet the 18 ton requirement: the standard minimum bending diameter for ½” wire rope is 10”. (This would be an ideal choice for this application.)

This is the workshop from The Professional Rigger newsletter, circa 1986.

COMMENTS