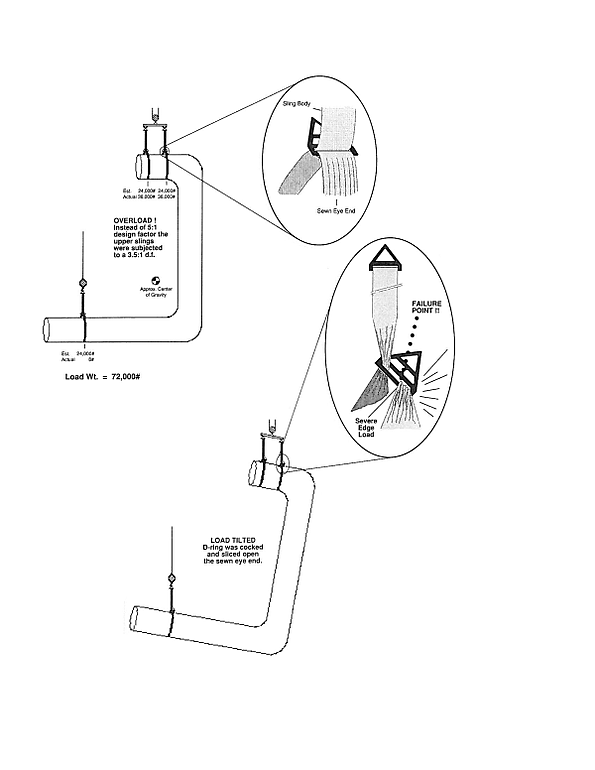

Each of the three slings (type SCH2-912 [2 ply, 12” wide]) had a rated capacity (lbs) of 33,600 vertical; 67,200 basket; and 25,200 choker. Had all three pick points been rigged as basket hitches, even the two slings from the strongback would have had sufficient capacity to carry the entire load. However, the riggers opted to use choker hitches, hoping for better friction between the slings and the pipe. By the use of choker hitches and not realizing the location of the center of gravity, the two upper slings were subjected to a load of approximately 36,000 lbs per sling, with little or no load on the third remaining sling.

The whipline and third sling were then used to adjust the pipe to a level plane for final placement. In the tilting process, the webbing, which made up the running portion of the body of the sling as it passed through the triangular D-ring, slid and gathered into one end of the D-ring. As a result, the sewn eye secured to the D-ring slid to the other end of the opening, and the D-ring acted as a letter opener, slicing the sewn eye webbing from one side to the other.

Once the first strongback sling failed, the second strongback sling, also cocked out of alignment, received close to the entire load weight and subsequently failed. The third sling, which was subjected to a shock load as a result of the pipe falling and tumbling, and it’s D-ring ripped out of its attached eye.

Comments & Observations

- Synthetic web slings with triangular D-rings are great for many applications. They must be used properly and should NEVER be subjected to load tilting as in this case. Web slings are very forgiving but when edge loaded they will not be able to bear the load over the width of the material and will simply not “stretch” to adjust to edge loading.

- Use two double wrapped basket hitches at the top end of the load. The double wrap helps with friction and control while the basket hitch provides a much greater capacity.

- One of the contributing factors to the accident was the crew not realizing the location of the CG and consequently overloading two slings. Riggers should spend a few extra minutes considering the load’s CG and determining which slings will share what portion of the load. Knowledge of the approximate CG is a major item on a Rigger’s Checklist.

Happy Rigging, Mike Parnell.

P.S. Load Control and CG is demonstrated in our Journeyman Rigger Training and Master Rigger Training Courses.

This is an article from The Professional Rigger newsletter, 1990.

COMMENTS